Heating ventilation and air-conditioning (HVAC) systems play an important role in preventing the spread of diseases via airborne or aerosol-based transmission. This article introduces an airflow control method and Azbil’s venturi airflow control valves that have been used in hospitals in Tokyo to handle COVID-19 cases.

Airborne Infection Isolation Rooms

The latest research in COVID-19 has emphasised the importance of Airborne Infection Isolation Rooms (AIIRs) in hospitals. In order to prevent hospital-acquired infections, also known as nosocomial infections, it is necessary to set up AIIRs with appropriate negative pressure and inward airflow. From the viewpoint of public health, the ideal setting is to set up sufficient AIIRs in as many hospitals as possible; but from the viewpoint of hospital management, this means increasing needs for space and high initial and operational costs, especially when the facilities will become redundant during the normal periods. Ideally, patients with an airborne disease should be placed in a negative-pressure room, but in reality, this may not always be possible.

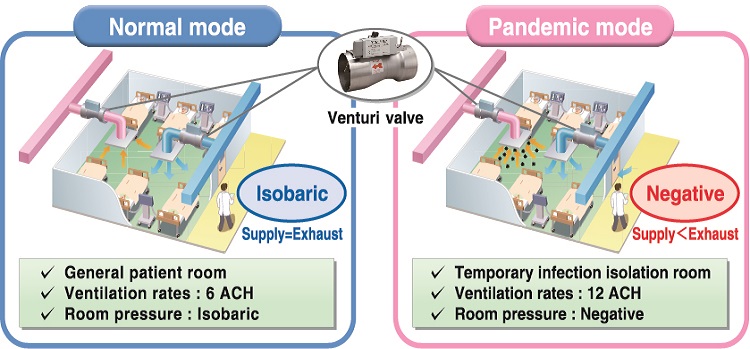

Fig. 1 Temporary negative-pressure isolation (TNPI) room using an HVAC system with a “pandemic mode”

An HVAC system with a ‘pandemic mode’ can be an effective solution to solve this issue. As depicted in Fig. 1, the HVAC system is available in two modes. The first is characterised by normal air changes and equal pressure between rooms and surrounding spaces. The second one, which is to be used during a pandemic, features increased air changes with negative pressure and inward airflow from the surroundings. According to Joint Commission International (JCI) Accreditation Standards for Hospitals, if an existing building structure prevents the construction of an immediate negative-pressure room, the hospital may construct a Temporary Negative-Pressure Isolation (TNPI) facility.

During the H1N1 pandemic in 2009, as part of the pandemic countermeasures, an HVAC system with a pandemic mode was installed in two designated hospitals in Tokyo, which have also been treating COVID-19 patients in the current pandemic. This system was able to significantly increase the number of beds to accommodate patients with severe infections.

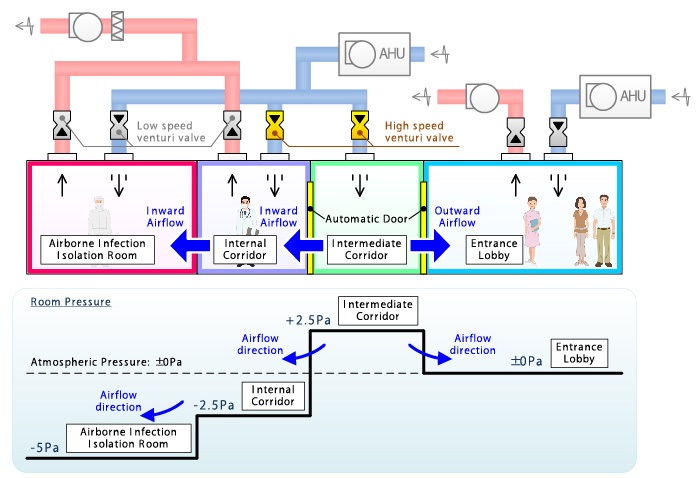

Fig. 2 Creating a pressure “embankment” to prevent cross contamination in “pandemic mode” using a high-speed VAV device

Controlling the Common Areas

Preventing airborne transmission in public areas such as in the lobbies or entrances is also necessary to prevent nosocomial infection from the patients to visitors and healthcare providers, and vice versa. As depicted in Fig. 2, an effective approach would be to build an intermediate corridor halfway between the public areas and the wards’ internal corridors—a narrow space with positive pressure serving as an airlock to create an embankment of pressurised air.

The doors at both ends of the intermediate corridor should be automatic to allow for a convenient passage for stretchers or large equipment. An interlock should also be activated to prevent both doors from opening at the same time. When an automatic door opens, in order to prevent the dispersion of contaminated air, it is necessary to increase the supply of airflow into the intermediate corridor, which will increase the directional airflow into the adjacent space. Since this airflow control would require a quick response to the opening and closing of the automatic doors, it is necessary to install a high-speed Variable Air Volume (VAV) device with a response time of one second or less.

Reliable and Accurate Airflow Control

In order to prevent airborne and aerosol-based transmission and to protect healthcare providers, airflow control should also be accurate and reliable. There are two common methods of control. The first is known as volumetric offset control, which creates an accurate inward (or outward) directional airflow between corridors and rooms by using VAV or Constant Air Volume (CAV) devices. A volumetric offset is created by maintaining a higher volume of exhaust air than supply air. The second method is direct pressure control, which adjusts the VAV device or the motor damper based on the measured room pressure values.

Although both methods are able to create different room pressure levels, particularly in spaces with high door traffic and low levels of airtightness, volumetric offsetcontrol may be more accurate and reliable. When a door is opened, the pressure difference between the spaces will instantly become zero. The VAVs or motor dampers used in direct pressure control tend to respond excessively to the room pressure values, which may result in unstable room pressure or airflow. In spaces where airtightness level is low, this method might fail since the measured room pressure values would only be minute. Also, a very small error occurring in the room pressure sensor would destabilise the system.

A careful selection of the VAV/CAV airflow control device is paramount. If air volume is altered due to switching to the pandemic mode, there will be a great change in the distribution of duct pressure in the HVAC system. Also, when there are strong winds outside of the building—especially onto the exhaust port of the exhaust fan or the outdoor air inlet of the air handling unit—the duct pressure will severely fluctuate. In order to control airflow accurately and reliably, the system needs to be able to control airflow to the set point without being affected by changes in the duct pressure. Such a system is commonly known as pressure independent mechanism.

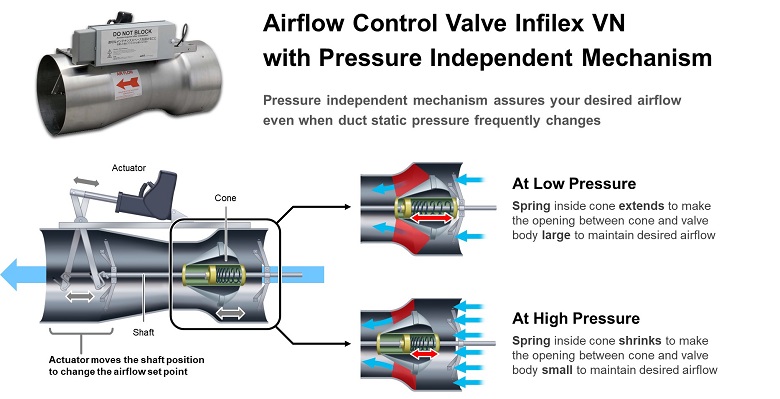

Fig. 3 The accurate and highly reliable airflow control valve InfilexVN with pressure independent mechanism

As depicted in Fig. 3, the venturi airflow control valve InfilexVN offered by Azbil is equipped with a superior pressure independent mechanism. This is made possible by the expansion and contraction function of the spring in the inner part of the cone and the curve of the venturi tube. Such a valve suits perfectly with the HVAC systems used for pandemic countermeasures. Indeed, it has been adopted extensively in healthcare and research facilities, with extensive evidence of its capabilities.

CONCLUSION

Pandemic emergencies demand a swift and apt response with no room for failure. Low performing VAV/CAV devices will cause a disastrous situation. Healthcare providers are fighting tirelessly to save lives. Provision of quality devices that can perform accurately without causing concern for safety is very important. Proper technology such as Azbil’s venturi airflow control valve InfilexVN will provide accurate and highly reliable airflow control to equip healthcare facilities; hence allowing them to treat patients and protect medical staff at the same time.