The primary objective of healthcare management is to build consumer focused integrated primary health system improving quality, safety, access, performance and reducing inequity. In the healthcare system, logistics is governed by internal and external supply chains. In the case of internal supply chains, healthcare providers and patients require services with short lead time. Whereas, the external chain including manufacturers and distributors of healthcare products mainly focuses on cost reduction. Well, the entire healthcare system's focus is to provide service to patients, which is often limited due to time constraints.

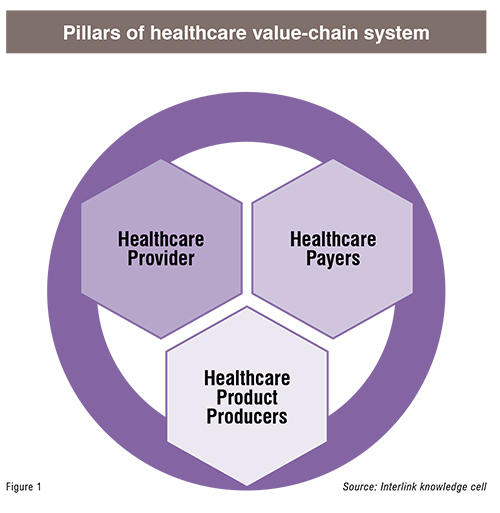

Healthcare is a crucial system governed by humanistic approaches that emphasise the personal value of an individual. Human emotions and values form the core of the system which is efficiently supported by the creativity and proactive nature of healthcare staff. The approach has to be buoyant and focus should be on developing the noble human capacity to tackle the patient’s hardship, pain and despair. Basically, there are 3 pillars of healthcare system, can be called the 3 Ps: the providers of healthcare, the payers for healthcare, and the producers of healthcare products. These 3 Ps together form the value chain of the healthcare system. (Figure 1)

Advanced technologies and increasing healthcare awareness has increased the patients’ knowledge. Moreover, technology coupled with feedback forms and review forms further increases the competitiveness in the healthcare market. In fact, technology is reshaping the healthcare industry in an irreversible way. Previously, the only factor that was considered by patients while choosing the hospital or clinic is the quality of treatment provided. But today, the concept of quality, the technology adopted plus the effect of treatment with respect to time all is studied through internet reviews to find the best fit. Knowing all this, the healthcare management has to consider how business practices are affecting patient care. This might include internal and external stakeholders empowering the total healthcare system.

A supply chain management includes physical as well as informational resources to deliver a good or a service to the final consumer. In the broadest sense, a supply chain includes all activities related to production, processing, warehousing, and transportation. Hence, large multispecialty hospitals require specialised skills, digitalised IT systems, and team of people to ensure timely delivery of goods and services. Items involved internally in healthcare systems include drugs, medical equipment, catering, laundry, home-care products, waste management, information technology (IT), vehicle fleet management and general supplies.

Supply should be directly proportional to demand for smooth operations but that doesn't happen unless demand for available treatments and its financial perspectives are as per market opportunity. Simply put, a ‘centralised core approach’ to control the entire system might not be that useful, but a ‘centralised decision model’ can be used for coordination and is governed by a single decision-making system. Designing such a centralised system for hassle-free operations, effective communication and smooth coordination is necessary for better healthcare delivery.

COVID-19 has made us aware of acute shortages of materials like masks, PPE Kits, ventilators, intensive care unit (ICU) capacity, specific drugs, and, most importantly, the staff. The needs of healthcare resources were at peak and supply chain management has shown up their real time issues. I think, it is better to accept the reality and deal with it. Improving supply chain management is critical to ensure that healthcare providers have enough resources to do their duty. The internal supply chain should ensure delivery of each item at the appropriate time to ensure optimal treatment and patient safety.

In hospital operations, the supply chain is regarding patient, information, and material flows. Flow of medical devices, laboratory samples, sterilised instruments, pharmaceutical products, prosthetic, and everyday commodities such as meals and beverages all has to be managed simultaneously.

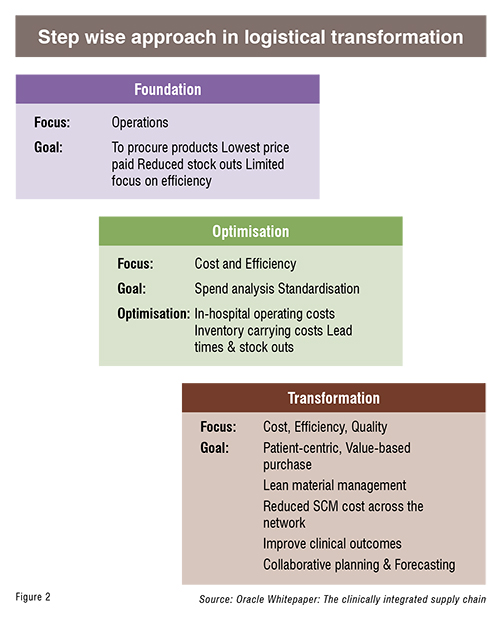

The material flows either towards or away from the hospital and within the hospital. So, hospital logistics is subjected to procurement, in-house storage, transportation to various wards, and waste management. Trolleys and other manual carriers are already used in various hospitals, while some premium hospitals use ATS systems for material flow. ATS is an automated material transport system that is expanding towards ‘Hospitals 4.0’. (Figure 2)

Few technologies that are included in an ATS system are as follows:

1. Automated Guided Vehicles (AGV): These are trolleys controlled by a computer and have limited load carrying capacity depending on its features. They are designed to travel along the floor of a facility without an onboard operator. They work on directions given by software and sensor-based guidance systems. There are various AGV types, depending on the requirements. Some typically used AGVs include Automated Guided Carts (AGC), Towing AGVs, Automated Forklifts that include Pallet Jack, Counterbalance, Outrigger, Very Narrow Aisle (VNA) AGV, Reach Trucks, Unit Load AGVs and other AGV designs for special applications.

The models that are used in hospital are mainly Automated Guided Carts (Hospital AGC) or Autonomous Mobile Robot (AMR). They are AGV on which a lifting platform is incorporated to carry a heavy load and transport of carts used in the distribution of goods.

Example: The New Royal Adelaide Hospital in Australia has installed around 25-strong fleet of RA-GV‘s (Robotic Automation’s Guided Vehicles). These are used to deliver drugs, laundry, sterilised items, food items, beverages (cold and hot), and are applied for waste management. The entire material flow between the patient wards, and the pharmacy, kitchens, and the other functional areas are managed by these AGVs.

2. Automated Mobile Robots (AMR): These are robots whose working is based on an array of onboard sensors, controlled by computers by encrypted mapping system. They can thus understand and move around surrounding area without an actual operator. This technology is widely applicable in warehouse area when coupled with Warehouse Execution Software (WES). This leads to better flexibility and efficiency in huge warehouse setups, whereby they can identify and avoid obstacles and reach to their locations even by rerouting if required.

Depending on the requirement they can be applied for:

Example: Smart applications like HelpMate and TUG enable autonomous mobile robots to transport materials and clinical supplies within the hospitals, and the laboratories. The robot operates in multiple ways, as it can be commanded to unload the cart at one or multiple destinations. TUG robots are guided by a laser scanner and thus can follow obstacle free path.

3. Electrified monorail system (EMS): As the name suggests, a monorail system managed electrically, is actually a conveyor system which travels across a low profile track. Guided by the cameras for a better security, it is equipped for commercial and healthcare applications. The following are the features of EMS;

Example: EMS technology is used at the NHS Hospital at South Mead, Bristol, in the laboratory section. It is applied as a laboratory automation system whereby samples are transported through a monorail, and has reduced manual workload, and integrated the monorail system with analysers and other robotic equipment to have a fully automated laboratory starting from patient to analyser to report generation.

The above mentioned technology can be applied in various departments depending upon the requirement. In case of routine operations, like sending or receiving materials or specimen such as blood samples or other pathological samples, can be configured with barcode or Radio frequency identification (RFID) chips. RFID chips are designed to capture electromagnetic field mentioned on tag which is labeled to the objects. The tags transmit digital data, usually an identifying inventory number, and thus help in tracking and monitoring the supply chain of an object.

For example, in case of managing the logistics in the sterile department, these chips can be labeled to each of the equipments used thereby. This enables hospitals to track the tagged equipment, instrument, at any given time within the hospital. Same can be done with food items or even drugs. Once a product is labeled, the same can be shared with the receiver, who can scan and track the item ensuring product’s authenticity.

To have an optimised and appropriate supply chain management across hospital activities, a complete overview of location, quantity, and availability of all items is crucial. The complex structure of management can be eased using digital tools such RFID chips. In today’s digitised world, use of software integrated services and robotics like technology is common. Though the tools are designed for specific activities, all such activities are linked to a common interface which is handled by a team of people having decision-making capability. This forms a central decisionmaking team for all logistical processes and ensures efficient material flow in real-time. Such an approach allows hospital staff to simply follow the steps as indicated by the software.

In hospitals, a concept called “the iron triangle” relates to cost, quality, and access. These three main criteria form the pillars of healthcare services. In India, patients suffer due to out-ofpocket expenses and that impact life adversely. Cost of healthcare increases as it moves from the public to the private sector as more technology starts coming in. Thus, use of economical technologies such as RFID at grass root level starting from primary healthcare services will provide efficient and reliable care to maximum number of patients. The Indian government has already started to integrate digital apps to automate data processes and procedural steps. Thus, a digitally managed logistic system will be soon replacing manual processes.

References:

https://www.oracle.com/a/ocom/docs/cisc-whitepaper.pdf

https://www.quirepace.co.uk/products/electric-track-vehicles/products/unicar/

https://www.agvnetwork.com/types-ofautomated-guided-vehicles